Sandwich wall panels are a type of modern building material that is used as thermal and cooling insulation to cover walls in various structures.

The insulation core and the sheets used in the layers around the foam sandwich panel vary greatly depending on the type of application. We recommend that you read the article “What is a sandwich panel?” before starting this text.

Type of Wall Sandwich Panels:

The following types of wall sandwich panels can be mentioned:

- Different Kinds of cold storages and freezing tunnels

- Coating sandwich panel

- Clean room sandwich panel

- Concealed screw sandwich panel

Using wall sandwich panels has several advantages compared to other traditional building materials, which we will discuss below.

Material of wall sandwich panel layers

The type and material of the layers on both sides of sandwich wall panels are generally made according to its application and consumer needs. The materials used in the manufacture of these layers include steel alloy sheets such as galvanized, aluzinc, steel, kraft paper, nylon, reinforced equipment foil, etc.

The core of sandwich wall panels is usually made of materials such as polyurethane, etc. This type of insulation is primarily a good thermal insulator against internal and external temperature transfer of the isolated environment, making it the best material for building industrial cold stores. This type of soundproof sandwich panel is also suitable for situations where sound waves need to be prevented from being transmitted.

Benefits of using wall sandwich panels

The most important advantages of using sandwich wall panels are high speed of implementation, easy transportation, and reduced related costs. For temporary constructions, sandwich wall panels provide the ability to dismantle and open them at any time, and it is even possible to reuse the same sandwich wall panels in another location for construction (even with different dimensions).

Compatibility with any type of structure, whether metal or concrete, is another advantage of wall sandwich panels. Of course, the technical standards regarding the installation of wall sandwich panels, due to their light weight, leave employers very free in choosing the building structure.

The following are the benefits of using this type of wall:

- Very light weight

- Ease of installation

- High execution speed

- Ease of transportation

- Ability to dismantle at any time

- Very low heat transfer coefficient

- Very good moisture insulation

- Very good sound insulation

- Washable

- No need for secondary coating

Therefore, considering the above, which characterize the advantages of wall sandwich panels compared to other building materials, the price of polyurethane sandwich panels will also be affordable.

Applications of wall sandwich panels

In addition to being used as an external wall in the walls of warehouses, cold stores, etc., sandwich panels can also be used as a separator or insulation in the floors and ceilings of various structures.

Application of wall sandwich panels as thermal insulation

In fact, a wall sandwich panel is a strong insulating layer reinforced with layers of steel alloy sheet. Depending on the consumer’s request, lighter and less expensive materials such as kraft paper, nylon, etc. can be used instead of two layers of steel alloy sheet.

Generally, this type of sandwich panel (both sides kraft paper or nylon) is used as thermal insulation in the floor of cold stores (under the concrete layer) or walls that require thermal or acoustic insulation.

Application of wall sandwich panels for roofs

As mentioned, wall sandwich panels can also be used as roof elements. In final or external covering roofs, depending on the conditions, if there is no need for a trapezoidal shape of the roof sandwich panel to direct rainwater (for example, building a shed inside a shed), this type of sandwich panel shows its application.

Also, due to the smooth surface of wall sandwich panels, this type of sandwich panel can serve as a ceiling or floor separating two floors that have the necessary structure.

If steel alloys such as galvanized, aluzinc, aluminum, etc. are used as the outer layers of the wall sandwich panel, the covering sheet can be rolled under a special mechanism called forming, according to the consumer’s needs, to enhance its strength and stability.

Of course, the smooth, unrolled, or so-called neckless type of this sandwich panel is also widely used in clean rooms or sanitary clean rooms due to its ease of washing and disinfection.

Application of wall sandwich panels in the construction of cold storage and freezing tunnels

One of the main uses of sandwich wall panels is in the construction of cold stores and food and hygiene freezing tunnels. Due to the excellent thermal insulation of polyurethane foam and the use of steel alloy sheets in the outer layers of sandwich wall panels, this type of wall is the best high-performance insulation for the construction of industrial cold stores.

Application of wall sandwich panels in the construction of prefabricated houses and cabins

Another major use of wall sandwich panels is in the construction of prefabricated houses and cabins of various sizes. From a small storage room or bathroom in the corner of the yard to huge industrial sheds, everything is made of wall sandwich panels today.

In general, the type and material of the layers on both sides of the sandwich wall panels are generally similar. However, depending on its application and the needs of the consumer, different materials such as kraft paper, nylon, etc. can be used on one side and another material such as steel alloy sheets on the other side of the sandwich wall panel.This type of sandwich panel is also used in places that require insulation and a secondary coating for washing, etc.

Today, due to the expansion of the construction industry, the use of new construction materials has no specific limits and the consumer determines the type of use of materials in his project. However, the history of the use of wall sandwich panels mainly shows itself in the following cases:

- Industrial sheds

- Sports halls

- Entertainment halls

- Food and health production halls

- Kitchens

- Clean room or industrial cleanrooms

- Industrial cold storage

- Food and hygiene freezing tunnels

- Prefabricated houses and cabins

- Small and large warehouses

- and…

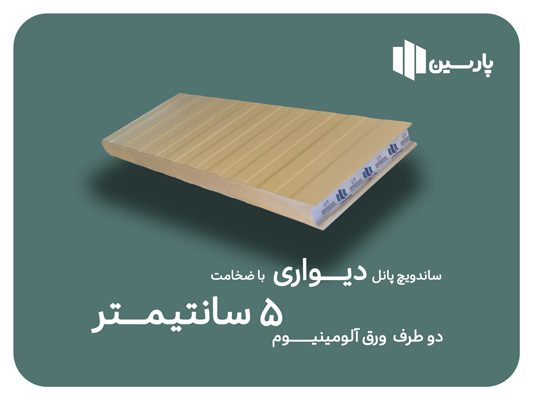

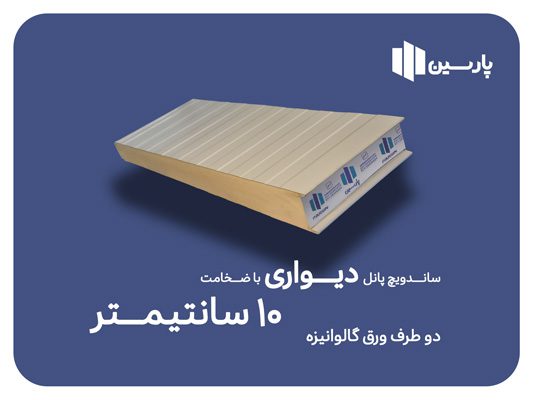

Types of wall sandwich panels in terms of sheet type and foam thickness

Parsin Gostar Company’s products include a wide variety of sandwich panel foam sheet types and thicknesses.

As mentioned, in sandwich panel production, depending on the type of application, the surrounding layers can be made of galvanized, aluzinc, aluminum, steel, or kraft paper, nylon, reinforced aluminum foil, etc.

Among them, galvanized sandwich panels are considered the most widely used type of wall panel. In the production of this type of sandwich panel, the insulating core is polyurethane foam and the sides are covered with galvanized sheet.

However, the thickness of the sandwich panel and the type of sheet used in it should be determined based on the weather conditions and the type of use of the building.

Steel alloys used as wall sandwich panel coatings come in a wide range of thicknesses from 0.4 mm to 0.7 mm.

Of course, it is worth noting that all sheets come in a variety of colors and are coated with 25-micron thick super polyester on the outside and 7 microns of baked primer paint on the inside at the point where the sheet connects to the foam for better adhesion.

The thickness of the foam in wall sandwich panels can vary from 2 cm to 15 cm. Sandwich panel manufacturing companiespresent their sandwich panels in different ways.

Some companies produce a few specific thicknesses, and others, like Parsin Company, have the ability to produce all thicknesses within 1 cm. Depending on the type of consumer’s need, different thicknesses of sandwich panels are used. For example, to implement an internal dividing wall or partition a food production hall, etc. Thinner wall sandwich panels are used.

Also, in projects where the difference between internal and external temperatures is high, such as industrial cold stores, freezing tunnels, sheds in tropical or cold regions, etc., sandwich wall panels with higher thickness are used.

Finally, it should be said that due to Parsin’s continuous production line, it is possible to produce sandwich panels with different lengths required by the consumer. The only limitation for the consumer regarding the use of long-length sandwich panels is the method of its implementation and transportation restrictions.