What is flushing?

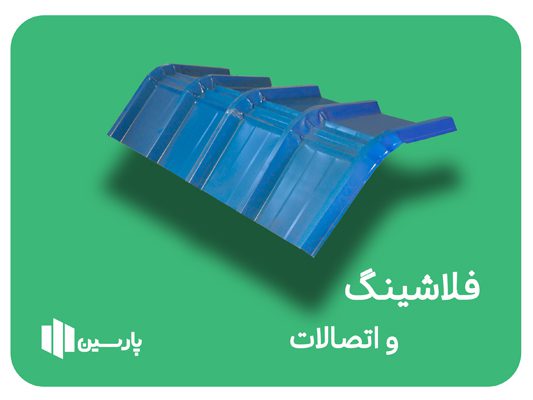

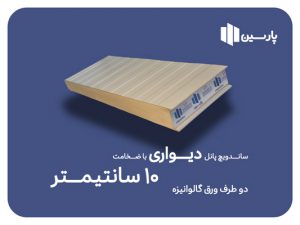

In fact, any type of curved covering, usually made of galvanized sheet metal and used to cover various points of work, is called flushing. Flushings have the function of unifying the facade (interior and exterior), sealing, decorating, and even connecting sandwich panels to each other as joints. Of course, flashings sometimes also serve the purpose of connecting sandwich panels to external surfaces to ensure continuity of the external facade. Flashings are pieces of sandwich panel covering sheet (galvanized, aluzinc, etc.) that are often used to seal the facade and hide the corners of the end of the work in the roof areas (gable and flat), eaves, parapets, etc. Flushing is usually attached to sandwich panels using screws or rivets.

These tools are manufactured and produced from different materials (galvanized sheets, aluzinc, aluminum, and PVC) in different dimensions and thicknesses, depending on the type, location of use, and type of project, and upon consumer request.

Flushings are produced in different types and sizes. They may even be produced based on the customer’s custom dimensions depending on the application in the project. However, Parsin Company generally produces several types of flushings with standard sizes and applications, the types of which are as follows.

Types of functional flushing

L-Angle Flashing

U-Channel Flashing

Hip Ridge Flashing

Ridge Flashing

Valley Flashing (Under Ridge)

Hollow Roof Step Flashing

Solid Roof Step Flashing

Purpose of Using Flashings

Each material, depending on its scope of use, uses a type of covering tool to seal and complete its appearance. For example, materials such as MDF sheets use PVC strips or plasterboards use mesh strips and putty. The covering tools of sandwich panels are flashings. The interesting thing is that the dimensions of the flush mounts are determined by the consumer. The type of color, its dimensions, and even its application can be determined by the consumer.