Sandwich panels or prefabricated panels are one of the common and modern building materials that play an important role in reducing the weight of structures, while also having other features such as high strength, proper insulation, easy installation, etc. Sandwich panels have various types that differ in terms of technical information and application. In this article, we intend to discuss the types of sandwich panels in terms of body material and their applications in the construction industry.

Types of sandwich panels and their applications

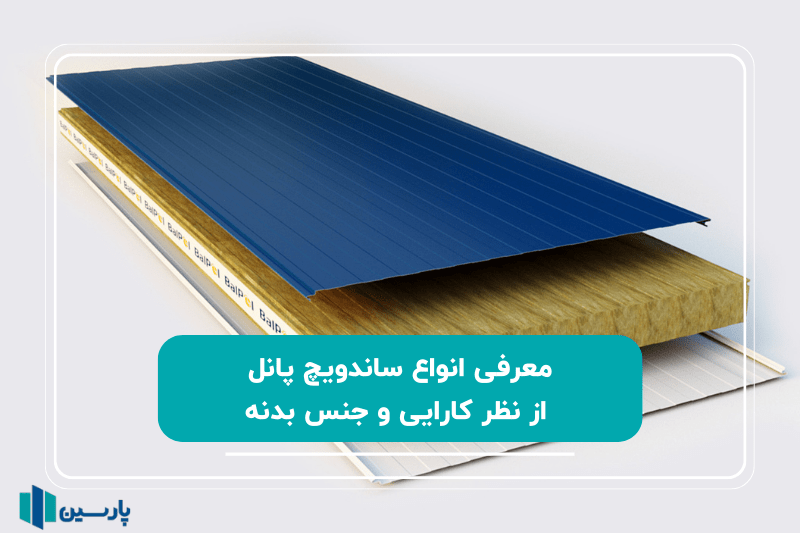

Sandwich panels are produced in two types: wall and ceiling. In general, sandwich panel consists of an outer layer that is generally made of metals such as aluminum, zinc, galvanized, etc. There is a middle section in prefabricated panels called the insulation core and it is made of foam. Insulation foam also generally has various materials including polyurethane, polystyrene, glass wool, rock wool, etc. The combination of each of these materials together in the manufacture of sandwich panels makes these prefabricated panels have a special application.

Generally, the type of sandwich panels is named after its insulating foam, for example, a polyurethane sandwich panel is a panel made from polyurethane foam. Below, we will get acquainted with the most common sandwich panels on the market in terms of construction materials.

Polyurethane sandwich panels

Polyurethane is one of the best types of insulating foams for sandwich panels. These foams have a good density and are excellent insulators for both heat and cold. Light weight and high strength and durability are two other features that can be considered for polyurethane sandwich panels. Polyurethane panels are available in two types: ceiling and wall, and are used for various purposes, including the construction of cold storage, clean rooms, ceilings or walls of residential structures, etc.

Rock wool sandwich panel

Rock wool is made from basalt, a type of igneous rock, which is why it is considered a very good insulator against direct heat and flame and is a kind of fireproof insulator. Rock wool panels are used in the construction of industrial structures due to their good insulation properties. Rock wool panels are produced as both wall and ceiling sandwich panels.

Polystyrene sandwich panels

These sandwich panels use polystyrene foam, also known as Unolite. These types of sandwich panels are very light and cheap, but the low density of polystyrene means that, despite their excellent resistance to moisture, they are very poor in terms of thermal insulation. Also, these types of sandwich panels are very vulnerable when exposed to direct flame. Polystyrene sandwich panels are used in the construction of various structures.

Types of sandwich panels in terms of application

Prefabricated panels can also be classified according to their application in construction. In terms of application, sandwich panels are divided into different categories, which include:

Roof sandwich panel

Ceiling sandwich panels generally have a thickness of between 4 and 20 centimeters. These sandwich panels have a low thermal coefficient and are considered the best choice for saving energy. Usually, the outer layers of ceiling panels are made of aluzinc or galvanized. In the manufacture of these panels, polyurethane foam is often used as a suitable sound and heat insulator.

Sandwich wall panel

Wall sandwich panels are used as wall coverings. They are usually used in the construction of walls of housing units or industrial factories, etc. The central foam of these sandwich panels may be any of the materials polystyrene, polyurethane, rock wool or glass wool. These foams are considered good insulators for moisture and humidity.

Cold storage sandwich panels

The thickness of cold storage sandwich panels is between 8 and 20 centimeters and polyurethane compounds are used as insulation. As the name suggests, these prefabricated panels are used to build cold storage, industrial construction tunnels, and large buildings.

Fireproof sandwich panel

These sandwich panels are made of insulation with a very low thermal coefficient. The insulation used in their construction is very resistant to direct flame and does not melt or deform in the event of a fire. These panels are often used to build industrial furnaces. Rock wool insulation is a thermal and fireproof insulation used in the manufacture of fireproof panels.

Types of sandwich panels in terms of body material

Another way to classify sandwich panels is by their coating material. Sandwich panels are divided into different types based on their body material, including aluzinc, galvanized, and aluminum sandwich panels.

Aluzinc sandwich panel

These panels are covered with two layers of Aluzinc sheet. Aluzinc is one of the most durable and best types of coating in prefabricated panels. Aluzinc sheets consist of an alloy of zinc, aluminum and a small amount of silicon. These coatings are good moisture insulators and have anti-corrosion and anti-oxidation properties. For this reason, Aluzinc sandwich panels are widely used in workshop and industrial environments.

Aluminum sandwich panel

Another common coating in sandwich panel manufacturing is aluminum, which is placed in the form of a coating on both sides of the insulating core. The features of this type of panel include very low weight, various thicknesses, and colorability. These panels have very good resistance and are often used as ceiling sandwich panels.

Galvanized sandwich panel

These types of panels are the most common types of sandwich panels. This coating is actually steel metal covered with a layer of zinc metal. These sandwich panels have good resistance and longevity. They do not corrode, rust, or rot in any way, and they are highly resistant to environmental factors such as wind, rain, and fire. These sandwich panels are used as wall and ceiling panels.

summary

Sandwich panels are divided into different types based on their application, type of insulation foam, and body coating. The choice of each of these factors is influential in determining the application of prefabricated panels and gives them specific characteristics. In this article, we will introduce the common types of sandwich panels on the market and their applications.

- 1 glass wool sandwich panel

- 2 sandwich panel thickness

- 3 decorative panel

- 4 rock wool sandiwch panel

- 5 what is clean room sandwich panel

- 6 acid resistant sandwich panel

- 7 types of sandwich panel

- 8 what is cold storage sandwich panel

- 9 concealed fixation joint

- 10 difference sandwich panel poly yurta poly styrene

- 11 corrosion resistant sandwich panel

- 12 aluminium sandwich panel

- 13 advantage and disadvantages of sandwich panel

- 14 fire resistant sandwich panels

- 15 what is modular sandwich panel

- 16 what is polystyrene sandwich panel

- 17 sandwich panel density

- 18 pvc sandwich panel