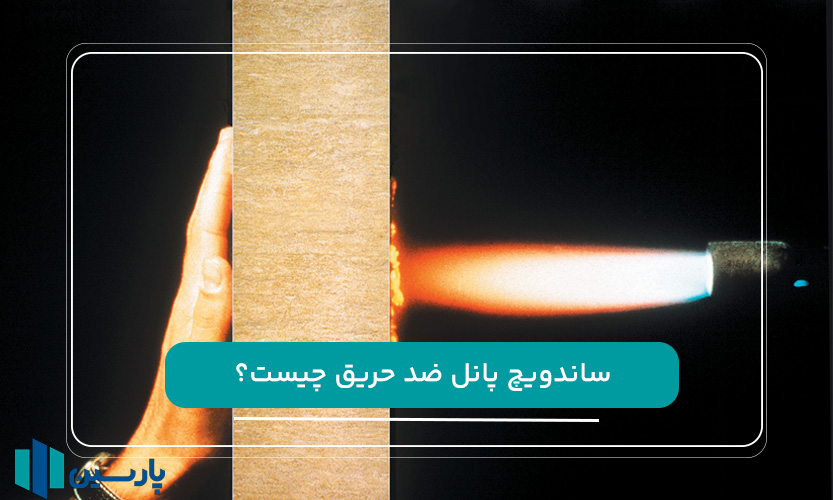

One of the most damaging incidents in various environments is fire damage, so it is of great importance to use materials that can minimize such damage. Fireproof sandwich panels are a safe and reliable choice in such situations. These panels have a similar structure to other sandwich panels, the only difference between them is the use of rock wool as an insulating foam in the central core, which makes these structures resistant to heat and heat from fire and has fireproof properties. Join us to learn more about fireproof sandwich panels.

What is a non-flammable sandwich panel?

Non-flammable sandwich panels, like other prefabricated panels, consist of an insulating section and two outer coverings. The most important difference between these prefabricated panels and others is the choice of insulating foam. In fireproof sandwich panels, insulating foam of the rock wool type is selected. These foams are highly resistant to heat and direct flame and are considered to be fireproof and fireproof.

Sometimes, Polyurethane foam is used in the manufacture of these panels. This foam also has high resistance to heat and direct heat. However, to increase this property, processes are usually used to convert polyurethane foam into a flame retardant material that is resistant to direct flame. Combining polyurethane materials with halogenated compounds is the main process used to achieve this feature. Using such panels in buildings increases the time the structure can withstand direct heat and flame, ultimately reducing damage from fire.

Application of fireproof sandwich panels

Fireproof sandwich panels are used in special and industrial projects. The construction of greenhouses, the construction of industrial furnaces and the use of fireproof panels in the construction of sheds where the possibility of fire and fire is high are considered the most important applications of this type of panels. The resistance of such sandwich panels reaches more than 2,000 degrees Celsius.

Considering the characteristics of these sandwich panels, it can be said that such a product can be used in all structures and increases the safety factor of the structure against fire. The most important application that can be considered for these panels is their use in commercial and office buildings, schools, sports halls, workshop sheds, warehouses, hospitals, and industrial factories with a high risk of fire.

Advantages of using fireproof sandwich panels

These panels are considered among the best prefabricated panels for wall and ceiling coverings due to their features. The most important advantages that can be mentioned in using such products are:

- High temperature resistance up to 2000 degrees Celsius

- Resistance to direct flame and thus reducing fire damage

- No spread of fire due to the panels’ high resistance to direct flame

- Organic and EPS insulations ignite much faster, while the fireproof density of these sandwich panels is 48 kg/m2.

- These panels are not only considered heat and fire insulation, but also good sound insulation.

- Very low heat transfer coefficient and reduced energy waste

- Lightweight yet durable

- Increasing the level of structural safety

Types of fireproof sandwich panels

Fireproof sandwich panels are designed and manufactured in different classes, which are referred to as fire retardant, slow-burning, and non-fireproof. Below, we will learn about each of these classes and their features:

B2 Sandwich panel

These fireproof panels have high resistance to fire and prevent the spread and spread of fire. Such panels are not produced in Iran and are generally available in the market as imports. The polyurethane foam of these panels is made from petroleum materials and its manufacturing process is also very complex and difficult.

B1 Sandwich panel

These types of panels are known as self-extinguishing sandwich panels and have good resistance to direct flames. These structures are designed in such a way that if there are flames, they will extinguish very quickly and spontaneously, thus preventing the spread of fire.

Sandwich panel with class A1

Fireproof and refractory materials are used in the construction of these panels, which is why they are very resistant and do not burn until they reach the melting point.

PIR sandwich panel

PRI is the abbreviation of polyisocyanurate. PRI has special properties, the most important of which is high resistance to direct flame. This type of fireproof sandwich panel is in the range between the two classes B1 and B2, which is neither completely fireproof nor self-extinguishing. The most common type of fireproof sandwich panel available in the Iranian market is of this type.

Fireproof sandwich panel price

The price of fireproof panels is affected by various factors, the most important of which are the type of insulating foam, the outer covering of the panel, the class of the fireproof panels, and the quality of their construction. The area, thickness of the panel, and the manufacturer’s brand are also among other things that play a direct role in determining the price of fireproof sandwich panels.

summary

Fireproof sandwich panels are one of the best types of prefabricated panels, the most important feature of which is high resistance to heat and direct flame. The use of such panels in various structures, due to their unique features, minimizes fire damage and increases the safety factor of the structure. Given that fireproof sandwich panels are produced in different types, their price is also determined by the panel class, construction quality, and the dimensions and thickness of the sandwich panel. The use of these panels is recommended in all structures, especially buildings where the possibility of fire is higher, including industrial workshops, sheds, warehouses, etc.

- 1 glass wool sandwich panel

- 2 sandwich panel thickness

- 3 decorative panel

- 4 rock wool sandiwch panel

- 5 what is clean room sandwich panel

- 6 acid resistant sandwich panel

- 7 types of sandwich panel

- 8 what is cold storage sandwich panel

- 9 concealed fixation joint

- 10 difference sandwich panel poly yurta poly styrene

- 11 corrosion resistant sandwich panel

- 12 aluminium sandwich panel

- 13 advantage and disadvantages of sandwich panel

- 14 fire resistant sandwich panels

- 15 what is modular sandwich panel

- 16 what is polystyrene sandwich panel

- 17 sandwich panel density

- 18 pvc sandwich panel