What is a duct panel?

Before any definition of duct panel is given, it is obvious that a definition should first be given regarding the duct itself. Ducts are air passage channels used in air conditioning to supply or remove air. These air flows can include supply air, return air, and exhaust air. A duct system is often called ductwork.Galvanized steel is the standard and most common material for duct construction. Now, because metal ducts themselves are heat exchange elements, they are covered with insulation on the outside to minimize this heat exchange along the duct path. This insulation is called duct insulation.

One of the best duct insulation is duct panels, which have several advantages over traditional insulation. Given the properties of polyurethane foam as a desirable thermal and moisture insulator, today duct panels are considered a huge revolution in the ventilation and installation industry. Accordingly, Parsin Gostar Junob Company has started producing this product and responding to the needs of its customers by using the most modern equipment and machinery.

Duct panel structure

Duct panels are a composite structure consisting of three components: a middle layer of polyurethane foam (PU) or polyisocyanurate foam (PIR) which acts as thermal insulation, and two layers on both sides as a middle layer covering, which are made of reinforced or ordinary aluminum foil.

Advantages of using duct panels:

- Preventing waste of energy and conditioned air in ventilation ducts and facilities.

- Fast installation (significantly saves construction time and, consequently, construction costs).

- Thermal and moisture insulation (very suitable for high-pressure ventilation systems).

- Sound insulation (due to the properties of polyurethane foam, duct panels can be used to reduce the noise of ventilation and utility ducts).

- Very light weight

- Fire resistant

- Completely airtight and waterproof

- Hygienic due to smooth and polished internal surface and the inability to accumulate bacteria

Applications of duct panels

As mentioned, the main use of duct panels is in insulating air ducts to prevent energy loss. However, due to their light weight and reasonable price, duct panels have found wider application today as insulation for various surfaces. For example, in the construction of an egg-raising greenhouse, if the initial sandwich panel covering is not required, duct panels are the best choice in terms of efficiency and cost. Therefore, any project that only requires insulation with a low temperature difference is the best application for duct panels.

Types of duct panels in terms of sheet type and foam thickness

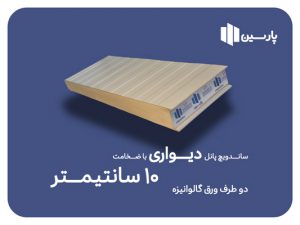

Duct panels produced by Parsin Company are produced with widths of 1 to 1.2 meters and thicknesses of 20 to 150 mm. The length of these duct panels also varies according to customer needs and considering transportation conditions.

Due to the characteristics of polyurethane foam, the middle core is mainly made of polyurethane foam (PU), but according to consumer needs, polyisocyanurate foam (PIR) can also be used as thermal insulation. There are also two layers on both sides as a middle layer covering, which can be produced from reinforced (for greater strength) or non-reinforced aluminum foil according to customer needs.