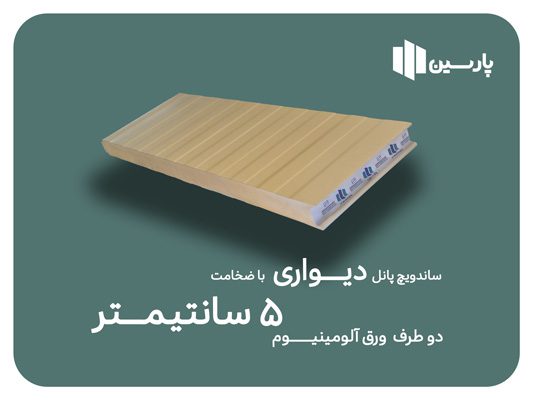

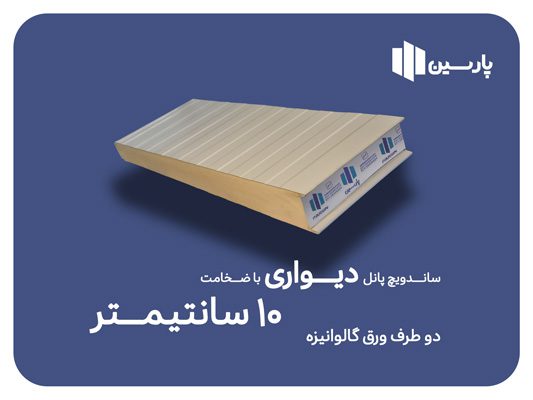

Parsin wall sandwich panels are suitable insulators against heat, humidity and sound and because of producing through continuous production line of Parsin, sandwich panels can be produced in diverse lengths (the only limitation faced lengthy sandwich panel is its implementation as well as difficult transportation). Dimension of Parsin wall sandwich panels varies from 2cm to 15cm.

Wall sandwich panels is an ideal solution for covering facing, use as indoor isolator and as a coating for flooring and roof in different structures. One of the other applications of wall sandwich panels is its use as wall and as roof of cold storage and freezing tunnels.

Application of Wall Sandwich Panels:

- Different Kinds of cold storages and freezing tunnels

- Industrial halls

- Sport and recreational saloons

- Residential buildings

- Prefabricated houses

- And….

Characteristics of sheets used in Parsin wall sandwich panels

Metal sheets used in the Parsin polyurethane sandwich panels are galvanized, aluminum, and zincalume (aluzinc) type which are of 0.4 to 0.7 mm thickness.

All metal sheets have various colors coated by a furnace super polyester with a thickness of 25 micron. A -7micron furnace primer color is used at the interface of the metal sheets and the foam for better adhesion.

Coating of polyurethane sandwich panel with galvanized plate, colored plates and aluminum plates is generally for external areas exposed to humidity and corrosion, while polyurethane sandwich panel with aluminum, polyurethane and paper foil is used for insulating flooring of cold storages (concrete substrate), apron of maritime structures and other cases.