In recent years, technological advances have led to the use of different raw materials to produce different thermal insulation in the construction industry. The amount of energy saved by using thermal insulation depends on factors such as the type of building, weather conditions, and the type of insulation used.Among the most widely used thermal insulators are polyurethane foam, polystyrene foam, glass wool, and rock wool, which are used as the middle layer in the production of various sandwich panels.

If you need a guide to familiarizing yourself with concepts related to sandwich panels, we recommend using the Parsin Gostar study roadmap.

What is the definition of sandwich panel?

Sandwich panels are lightweight composites with a three-layer structure. The insulating core, which forms the middle layer of the sandwich panels, is bounded on both sides by two metal layers.

The type of outer layers is determined by the type of application of the sandwich panel and the climatic conditions of the region. However, galvanized and aluminum sheets are among the most common coatings used in this industry.

In addition to the above, the material of the surrounding layers can be considered as Aluzinc sheet, steel, kraft paper, reinforced aluminum foil, and nylon, depending on the customer’s needs.

Parsin Gostar Jonoub Company, as the largest sandwich panel manufacturer in the south of the country, uses 5-component polyurethane foam in its products to achieve the highest level of thermal insulation.

Polyurethane foam used in the production of sandwich panels is a rigid polymer foam that has a higher insulation capacity than other thermal and refrigeration insulation materials and has received much attention today due to its high strength, light weight, and easy production and installation.

Types of sandwich panels

Sandwich panels are produced in two types: wall and ceiling. In general, sandwich panels consist of an outer layer that is generally made of metals such as aluminum, zinc, galvanized steel, etc. There is a middle section in prefabricated panels called the insulation core and is made of foam. Insulation foam is also generally made of various materials, including polyurethane, Polystyrene, glass wool, rock wool, etc. The combination of each of these materials in the manufacture of sandwich panels makes these prefabricated panels have a special application.

Generally, the type of sandwich panels is named after its insulating foam, for example, a polyurethane sandwich panel is a panel made of Polyurethane foam is produced. Below, we will get acquainted with the most common sandwich panels available on the market in terms of construction materials.

What are the uses of sandwich panels?

Sandwich panels have various uses; of course, their type of use also depends on the type of function and features they have.

These types of sheets are used as an external cladding in buildings and are mostly used in structures that require special resistance to weather, wind, humidity, etc.

As we said earlier, these structures are much more resistant to ordinary structures. Usually, they are factories, stadiums, shopping malls, swimming pools, industrial buildings, etc.They are places that need to be reinforced during construction, so it can be said that this type of insulation is being used more and more every day due to the need seen in construction.

What are the features of sandwich panels?

Sandwich panels have unique features that make them more common than other panels. Their unique features include the following:

- Easy to transport and move.

- Can be used in all climates.

- Very easy to install.

- It has a variety of colors and models that can be used in different projects.

- It reduces sound and heat transmission.

- It reduces moisture transfer into the structure.

- It can be washed and recycled in nature.

- It is resistant to natural disasters and external factors.

- It has high strength and durability despite its low weight.

- It is easy to maintain and does not cost much.

- It is chemical and biologically resistant and is also resistant to weather.

What are the reasons for using sandwich panels?

Light weight sandwich panel

Using sandwich panels in brick walls can reduce their weight by up to 30 times, and although it reduces the cost of infrastructure, it will increase the structure's resistance to natural disasters, floods, and storms.

High resistance of sandwich panels

Despite their light weight, sandwich panels have a very high resistance to applied pressure. This allows them to be used in the construction of prefabricated housing and walls.

Quality insulation

A compressed foam is sandwiched between two layers of sheet metal, which acts as a heat, moisture, and sound insulator. In certain models, these panels are fireproof and acoustic.

Resistance to cold and hot weather

Sandwich panels have very high resistance to various weather conditions, making them a good choice for structures located in cold and hot climates.

Ease of installation of sandwich panels

Sandwich panels are not manufactured on site, but are prefabricated and installed at the desired location, making them easier to install than other similar products.

Parsin Gostar sandwich panel.

Roof sandwich panel

A roof sandwich panel is a type of external roof covering that is made of lightweight materials.

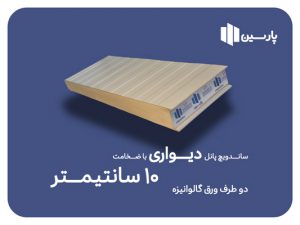

Wall Sandwich Panel

A sandwich wall panel is a type of interior or exterior wall separating coating that is made of lightweight materials.